Capabilities

Thanks to the experience of our technicians, our analytical and testing departments can answer the most diverse scientific inquiries with analysis with advanced technical instruments available and with the development of customized analytical procedures. Our researchers' team can tackle all different customer requests in real-time and follow the development of new solutions and products step-by-step, from the idea to its implementation. Our analytical departments handle around thousand analysis requests per year, performing chemical and morphological investigations. Analyses are carried out using Microscopy and X-ray techniques for the solid-state, instrumental, and analytical techniques with wet chemistry methods. These techniques provide quantitative answers on the morphology, type, composition, and crystallographic state of elements forming electrochemical coatings and solutions, solids, and gases involved during the operation of pilot and industrial cells.

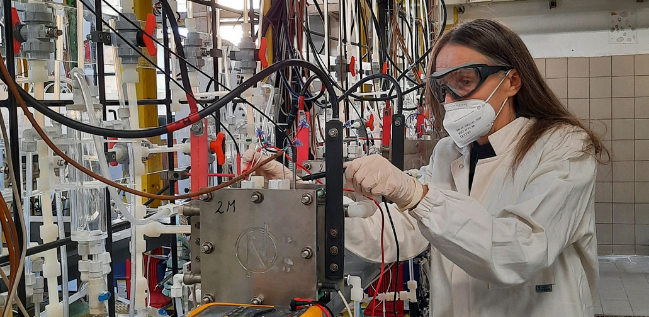

Our testing departments include accelerated life testing facilities that count more than 500 stations for chlorine, hydrogen, and oxygen-evolving electrodes used to characterize samples about new developments, industrial retains, post-operation residual life, manufacturing QC, and troubleshooting. In all laboratories, we have designed, installed, and operated different types of pilot cells that are representative of industrial electrolyzers for Chlor-Alkali, HCl-ODC electrolysis, and three different processes of Water Electrolysis (Alkaline, PEM, and AEM) to obtain primary data on electrodes, separators and electrodic packages in general, under accelerate life testing conditions. These cells are used for De Nora group experiments to supply our customers with high-quality electrodes and technical solutions.