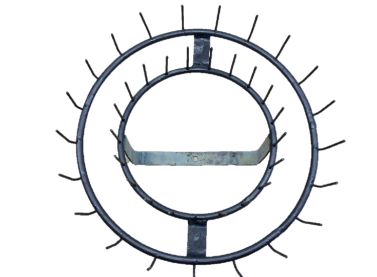

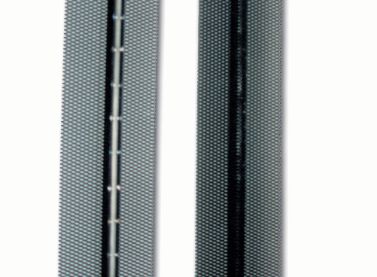

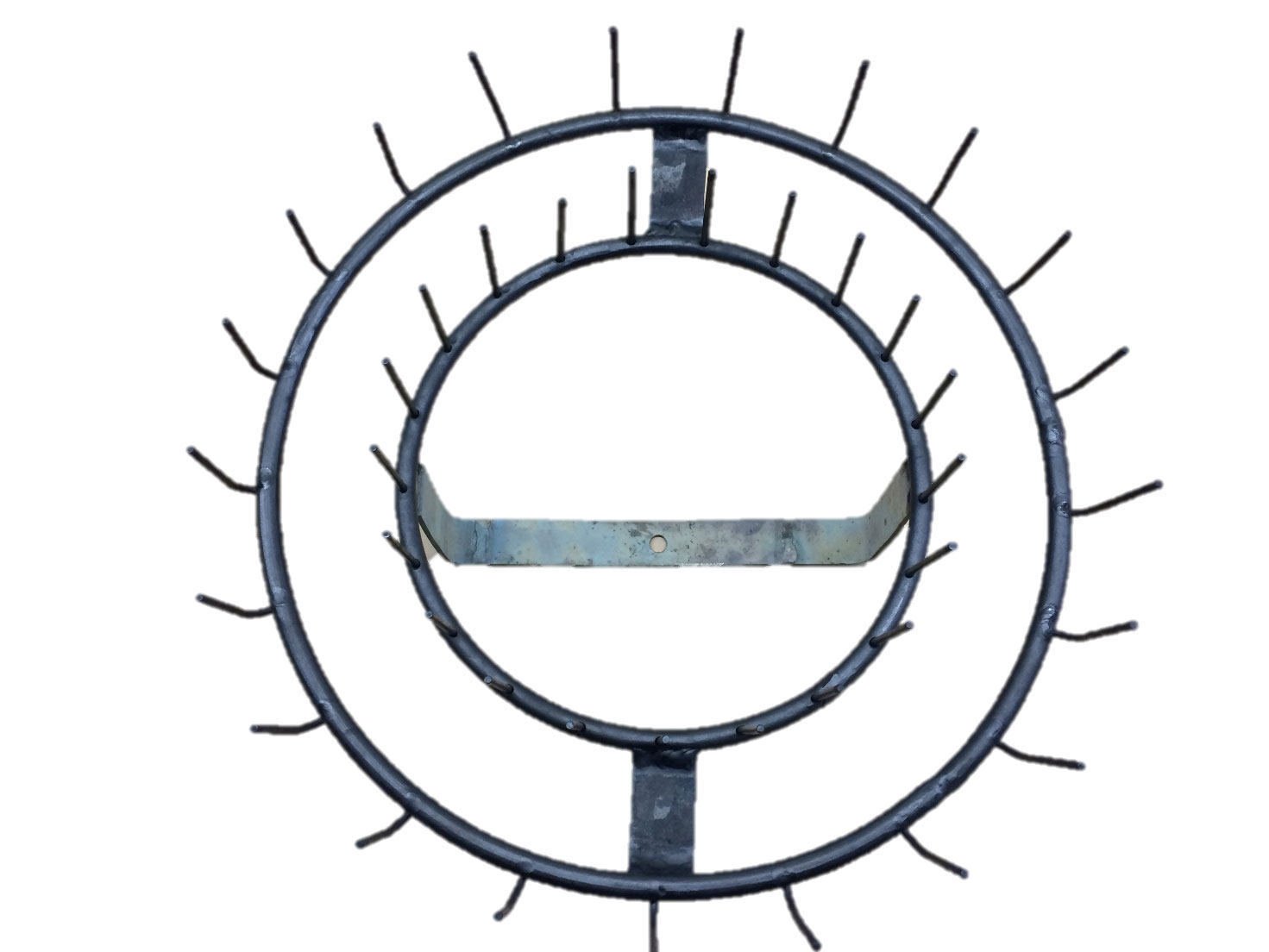

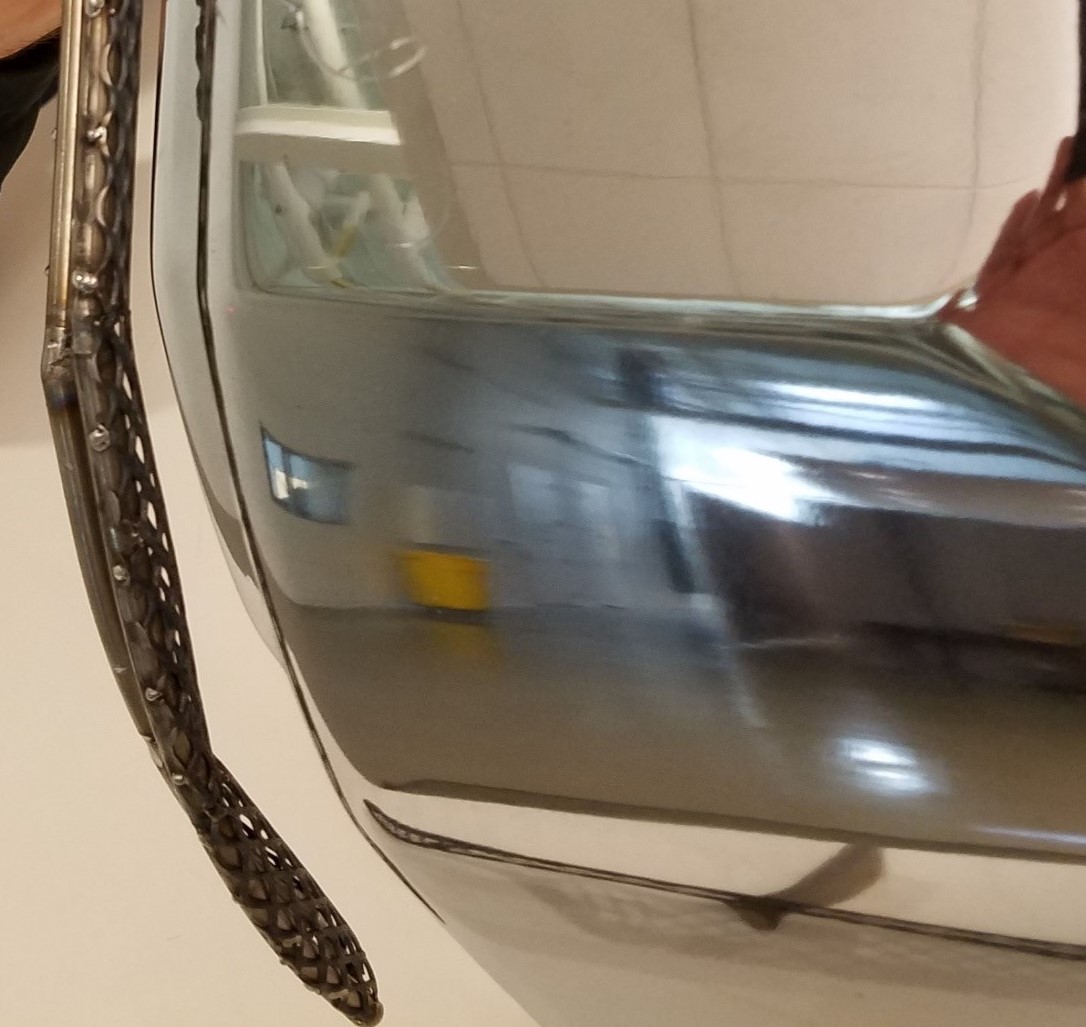

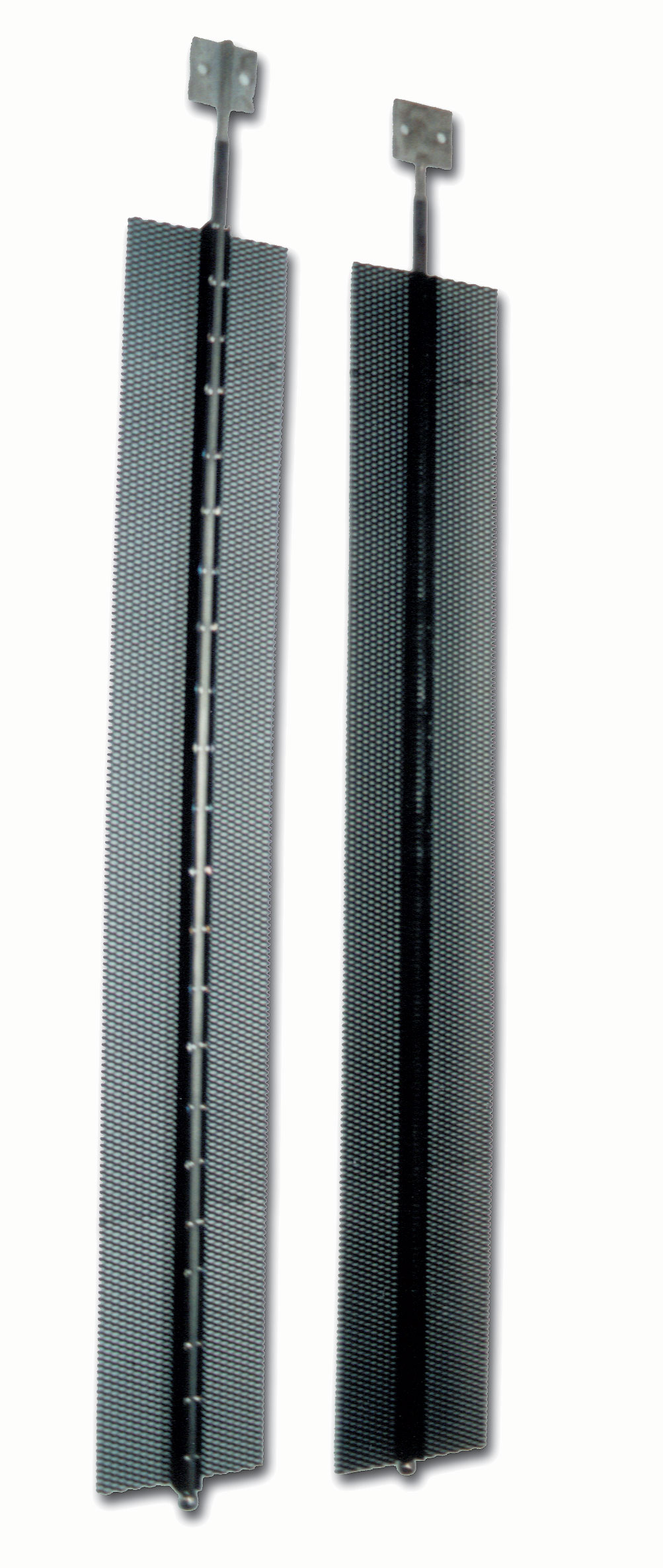

Auxiliary anodes, Hard chromium plating

De Nora offers a wide variety of anode solutions for hexavalent chrome. The primary customers of hexavalent chrome, automotive and decorative fixture markets, require enhanced localized chrome deposition due to the unique size and design of the parts. De Nora’s auxiliary anodes are a perfect solution for parts with unique geometries that need precise and accurate finishing.